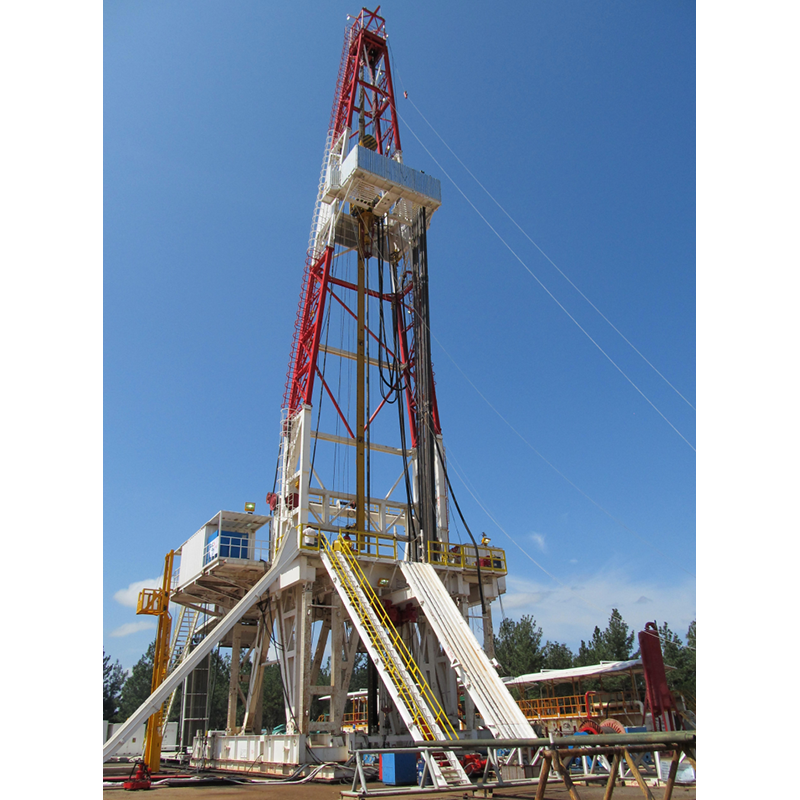

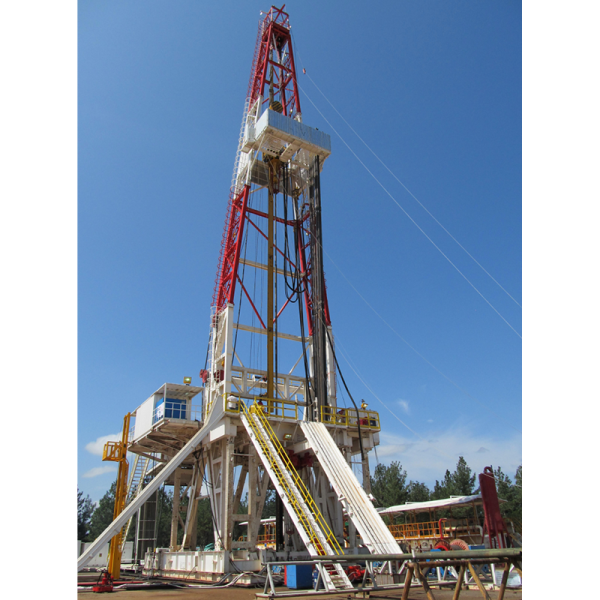

ZJ50/3150DB rig adopts swing up type substructure and K type mast, one time stringing can continuous raising, double motor single gear transmission driven single shaft double shift AC frequency conversion Drawworks, can realize double stages stepless speed regulation, improve the equipment reliability and operational economy. Electric drive control system adopts Siemens PLC and AC frequency conversion technology, high efficiency, high control precision, the whole rig control system adopts the redundant heat backup mode, compatible, fault-tolerant performance is good; Supporting 2 sets of F - 1300 triplex cylinder mud pumps, can improve drilling speed, ensures the bit reliable high-speed rotation, prolong the service life of the drill bit and improve drilling efficiency.

1.Give full play to the advantage of advanced digital AC frequency conversion electric transmission, and uses the machine, electricity, liquid, gas, digital control integration design, improve the control accuracy, simplifies the structure of drilling rig.

2. Equipment on the floor is installed at low position and overall hoisted. Reducing the workload of aerial work and improve the security.

3.Electric transmission adopts vector frequency conversion drive system and realize the fully digital control operation, obligate interface for remote fault diagnosis expert system, can realize the collection of control parameters and drilling parameters (signal), display, storage, printing, remote monitoring and management.

4.Realizing bit pressure, drilling rate, pump pressure, pump capacity to large range, high precision effectively control and greatly improved the drilling process. Using the characteristics of frequency conversion technology, make Drawworks hover at zero speed, changed the traditional way of driller operation.

5. The operation control system using dual PLC redundancy design, improve the reliability of the system.